Understanding the technical solutions to common production challenges is key to making an informed decision. These detailed answers explain how our machine’s technology ensures long-term stability, quality, and flexibility.

Q1: How do you keep the multi-flavor ratio stable over a long production run?

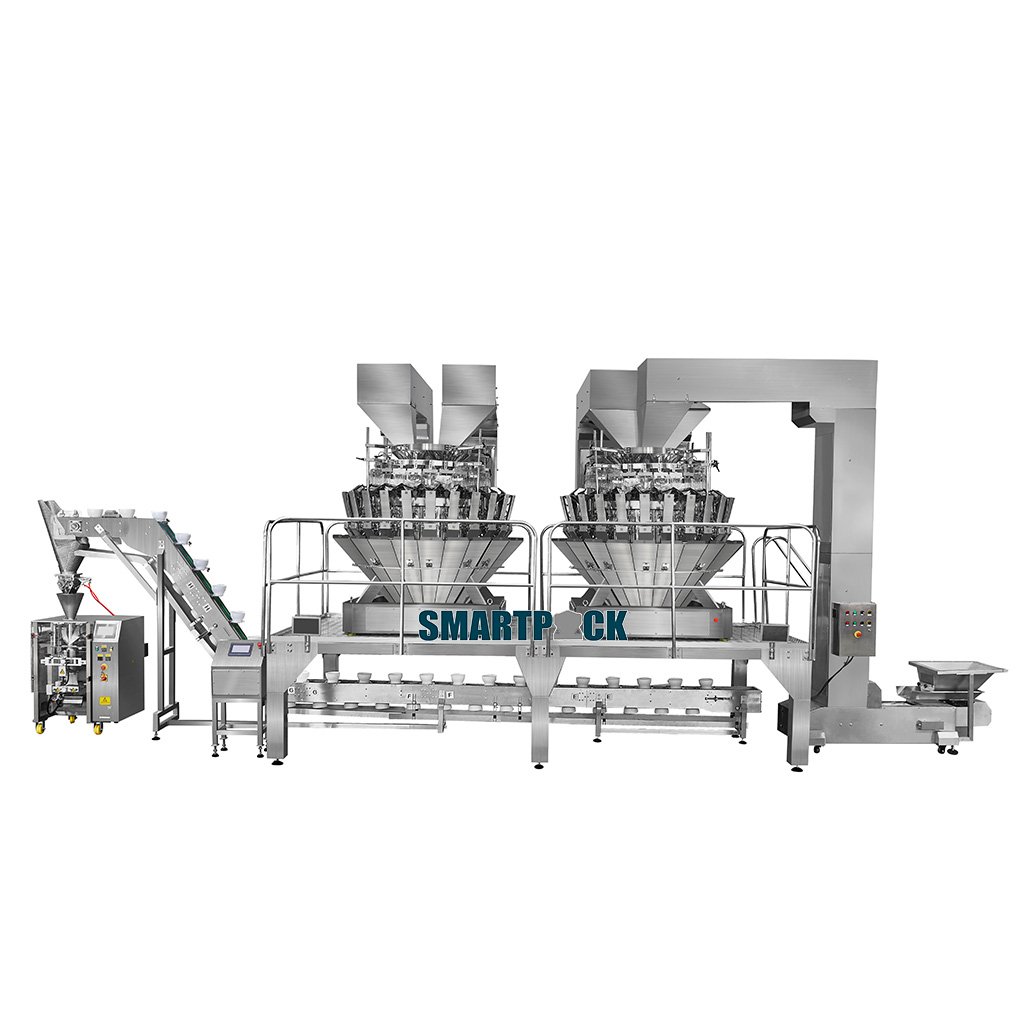

A1: The machine uses a two-level control system. First, each of the multiple weighers measures its assigned candy type independently to meet the recipe’s ratio. Then, an in-line checkweigher measures the final net weight of every bag. This data is fed back to the main controller, which makes tiny, automatic adjustments to the target weights of each weigher. This closed-loop system corrects for any drift and keeps the blend ratio and net weight accurate over thousands of bags.

Q2: Will a mix of small and large candies separate or layer in the bag?

A2: We designed the system to minimize this effect. The discharge chutes have features that buffer the product flow, and we make the drop distance from the weigher to the bag as short as possible. This reduces the chance for heavier or smaller pieces to settle. For particularly challenging mixes, we can also implement a two-stage filling process, which further ensures a uniform distribution.

Q3: How do you keep the mix of colors or shapes looking even?

A3: The control software has settings to manage how the different weighers discharge their product into the central chute. We can set thresholds for the minimum and maximum amount of product dropped from any single channel at one time. By controlling the timing and flow from each channel, we prevent clumping or color bias, ensuring a visually balanced mix in every package.

Q4: Should I use chain bags or single bags?

A4: Your choice depends on your retail channel. Chain bags, which are perforated for easy separation, are excellent for hanging on retail display racks or for selling as multi-packs. Single bags are better for individual sale or for packing into larger bulk boxes. The machine can be configured to produce either style, so you can choose based on your marketing strategy.

Q5: How does the checkweigher help correct the blend ratio?

A5: The checkweigher’s primary role is to verify the total net weight. However, its data is crucial for the entire system’s accuracy. The feedback from the checkweigher allows the main controller to understand if the total weight is consistently high or low. The controller then intelligently adjusts the target weights for all the individual weighers at the same time, maintaining the correct ratio while bringing the total weight closer to the target. This reduces product giveaway and ensures regulatory compliance.

Reviews

There are no reviews yet.