Description

The Smartpack Premium Pouch Meatball Packing Machine transforms pre-made pouches into retail-ready packages with precision multihead weigher technology. Perfect for premium meatball brands requiring sophisticated packaging presentation and portion accuracy.

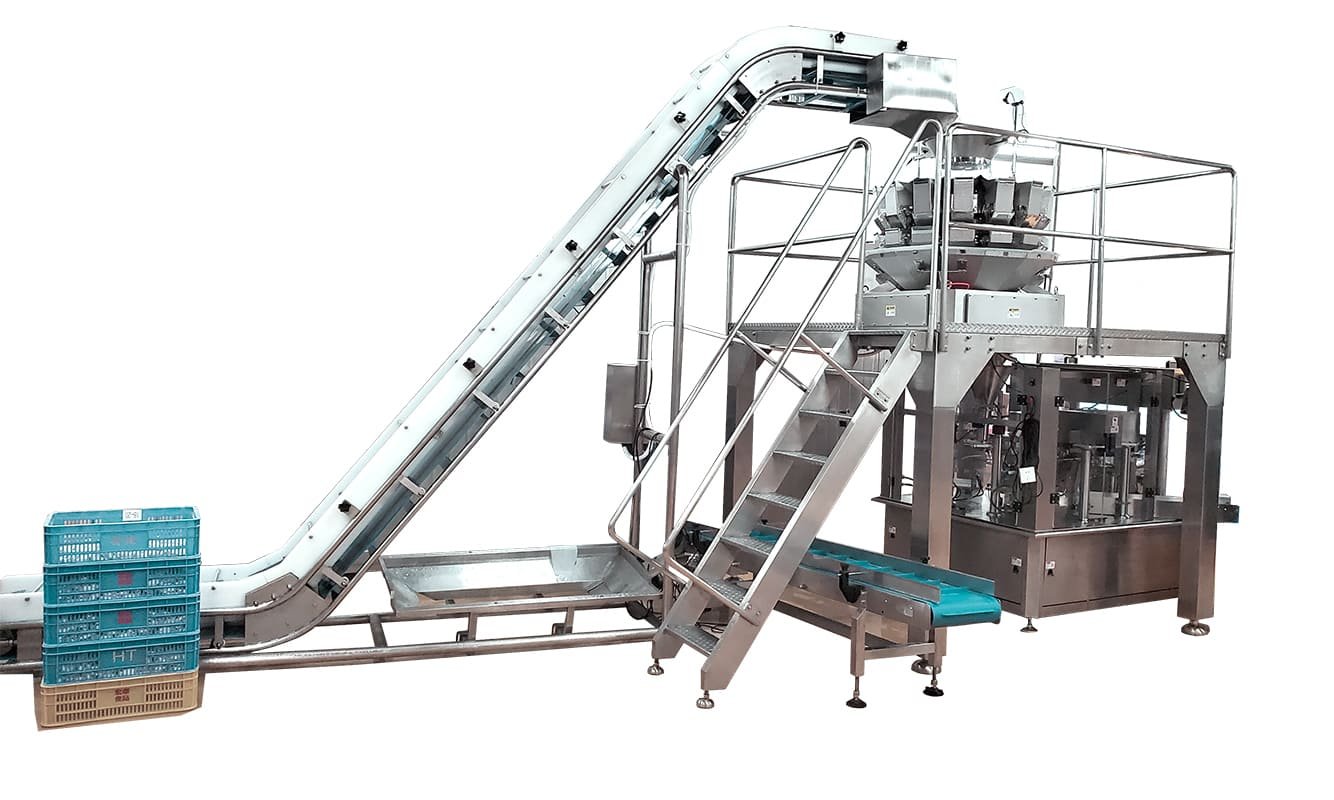

Machine List

- Incline conveyor

- Multihead weigher

- Support platform

- Rotary pouch packing machine

- Rotary collect table

Technical Specifications

| Name | Specification |

|---|---|

| Weigher Heads | 10/14 heads |

| Weighing Range | 10g – 1000g(10 head weigher), 10-2000 grams(14 head) |

| Accuracy | ±1.5 grams |

| Speed | 10-50 bags/minute |

| Bag Style | Premade pouches, zipper pouches, stand up pouches, doypack |

| Bag Size | Width 100-250mm, length 150-350mm |

| Film Material | Laminated film, single layer film |

| Power Supply | 220V, 50/60Hz |

| Air Pressure | 0.6-0.8 MPa |

Advantages

Retail-Ready Presentation

- Enhanced shelf appeal with custom pouch designs

- Resealable options for consumer convenience

- Clear product visibility through transparent windows

- Professional heat sealing for extended shelf life

Production Flexibility

- Easy product changeover in under 15 minutes

- Multiple pouch styles on single production run

- Reduced packaging material inventory requirements

- Premium positioning for higher margin products

Target Applications

- Retail grocery chains

- Specialty food producers

- Gourmet frozen food manufacturers

- Export-focused operations requiring attractive packaging

Applications & Benefits

Ideal for High-Volume Production

- Frozen food manufacturers

- Industrial food processors

- Private label producers

- Wholesale distribution centers

Operational Benefits

- Reduces labor costs by 60% compared to manual packaging

- Maximizes production throughput for bulk orders

- Maintains consistent portion control for regulatory compliance

- Space-efficient vertical design fits existing production lines

Frequently Asked Questions

Q1: What types of pouches can this machine handle?

A1: The machine accommodates stand-up pouches, zipper pouches, flat pouches, spout pouches, and custom-shaped pouches. Pouch width ranges from 100-250mm and length from 150-300mm.

Q2: Can it handle both meatballs and paste products like fish paste?

A2: Absolutely. The pouch packing machine can integrated multihead weigher and liquid pump, handles solid products like meatballs, semi-solid items, and paste consistencies. The multihead weigher automatically adjusts for different product densities.

Q3: How does the pouch opening system work?

A3: We use a combination of vacuum suction and mechanical gripper arms. The system includes sensors to detect if pouches fail to open properly, automatically rejecting faulty pouches.

Q4: What’s the accuracy for sticky or paste-like products?

A4: For paste products, we maintain ±1g accuracy. The weigher includes anti-stick coatings and vibration systems to ensure complete product release from hoppers.

Q5: Can the machine handle pouches with zippers or valves?

A5: Yes, the machine accommodates zipper pouches, valve pouches, and spout pouches. Special handling ensures these features remain functional after sealing.

Q6: How fast can it switch between different pouch sizes?

A6: Changeover between pouch sizes takes 8-12 minutes using quick-change tooling. The HMI stores recipes for up to 100 different pouch configurations.

Q7: What happens if a pouch is damaged during handling?

A7: Quality sensors detect damaged pouches before filling. These are automatically rejected to a separate collection area, preventing product waste.

Q8: Can it handle frozen meatballs without condensation issues?

A8: The machine includes heated zones around critical areas to prevent condensation. Optional nitrogen purging systems are available for extended shelf life packaging.

Q9: What’s the sealing temperature range and options?

A9: Sealing temperature ranges from 120°C to 220°C depending on pouch material. We offer heat sealing, ultrasonic sealing, and impulse sealing options.

Q10: How easy is it to clean between different products?

A10: The IP65 design allows complete washdown. Product contact surfaces are removable for thorough cleaning. Typical changeover cleaning takes 20-30 minutes.

Reviews

There are no reviews yet.