Description

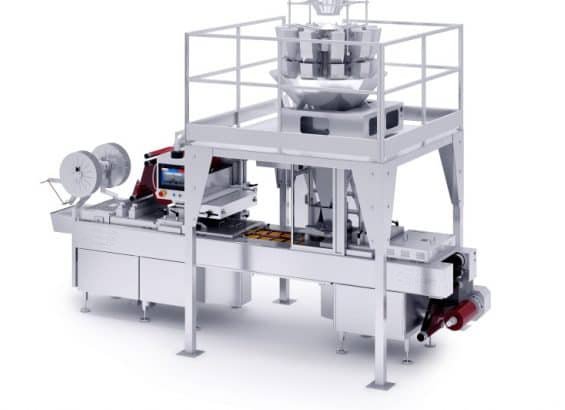

The Smartpack Thermoforming Vacuum Packaging System delivers maximum product protection through rigid tray packaging with integrated multihead weigher precision. This advanced system creates custom-formed trays while maintaining perfect portion control and extended shelf life.

Machine List

- Incline conveyor

- Multihead weigher

- Support platform

- Thermoforming vacuum packing machine

Technical Specifications

| Name | Specification |

|---|---|

| Weigher Heads | 10/14 heads |

| Weighing Range | 10g – 1000g(10 head weigher), 10-2000 grams(14 head) |

| Accuracy | ±1.5 grams |

| Speed | 40-50 trays/minute |

| Tray Size | Customizable from 150×100 mm to 300×200 mm |

| Film Material | Multi-layer barrier films, EVOH, PVDC options |

| Control Panel | 7″ touch screen |

| Power Supply | 220V, 50/60Hz |

| Thermoforming Capability | Creates rigid plastic trays in real-time |

Advantages

Maximum Freshness Preservation

- Vacuum sealing extends refrigerated shelf life from 3-5 days to 14-21 days

- 99.5% vacuum level removes virtually all oxygen, preventing oxidation and spoilage

- Modified Atmosphere Packaging (MAP) capability further extends shelf life for export markets

- Rigid tray construction prevents product compression and damage during transport

Enhanced Food Safety

- Vacuum environment eliminates bacterial growth conditions

- Sealed packaging prevents cross-contamination during storage and handling

- IP65 protection rating ensures hygienic production environment

- CE certification guarantees compliance with international food safety standards

Advanced Multihead Weigher Integration

- 14 independent weigh hoppers ensure consistent portioning

- Intelligent software minimizes product giveaway

- Quick product changeover between different meatball sizes

- Gentle handling system prevents product damage

Applications

- Premium Market Positioning

- High-end restaurant suppliers

- Retail delicatessen counters

- Export markets requiring extended shelf life

- Specialty meatball manufacturers

Long-Distance Distribution

- International shipping capabilities

- Warehouse storage optimization

- Reduced product damage during handling

- Professional presentation for foodservice

Frequently Asked Questions

Q1: What tray sizes and depths can be formed?

A1: Tray dimensions are available based on your specific requirements.

Q2: How long does the vacuum sealing extend shelf life?

A2: Vacuum sealing typically extends refrigerated shelf life to 14-21 days compared to 3-5 days for standard packaging. MAP (Modified Atmosphere Packaging) can extend this further.

Q3: Can the machine create multiple tray cavities?

A3: Yes, we offer single, double, and quad-cavity configurations. Multi-cavity trays are ideal for portion control and family-sized packages.

Q4: What film materials work best for thermoforming?

A4: We recommend multi-layer barrier films with EVOH or PVDC layers. Film thickness ranges from 200-500 microns for bottom web and 50-100 microns for lid film.

Q5: How does the heating system ensure uniform tray formation?

A5: Ceramic heating elements provide precise temperature control (±2°C). Multiple heating zones allow optimization for different film materials and tray designs.

Q6: Can it handle different meatball textures without damage?

A6: The gentle drop system and cushioned landing minimize product damage. Adjustable drop height accommodates delicate and firm products equally well.

Q7: What’s the vacuum level and sealing strength?

A7: Vacuum levels reach 99.5% with residual oxygen below 1%. Sealing strength exceeds 15N/15mm for secure package integrity during distribution.

Q8: How much film waste is generated?

A8: Skeletal waste (trim around trays) is typically 15-25% depending on tray size and spacing. Waste can be recycled through film reclaim systems.

Q9: How long does it take to change tray formats?

A9: Tray format changes require 20-30 minutes including tool changeover and system optimization. Recipe storage allows quick parameter recall.

Q10: Can it integrate with case packing systems?

A10: Yes, the discharge conveyor matches standard case packing equipment. Optional tray orientation and spacing systems optimize downstream automation.

Reviews

There are no reviews yet.