Your mixed candy bags are popular, but customers complain about inconsistent counts. This damages your brand and wastes money. There is a technology that solves this problem perfectly.

To keep piece count consistent, use a multihead weigher with a specialized piece counting function. This system combines advanced weight calculations and counting algorithms to ensure every bag gets the precise number of candies, even in a mixed-flavor batch.

I’ve talked with so many factory owners who face this exact issue. They produce a fantastic mix of gummy candies, but their reviews are filled with comments like, "I only got two cherry ones!" They try to fix it by overfilling the bags, but that just destroys their profit margins. Manual counting is out of the question; it's just too slow for modern production demands. This frustration is common, but the solution is surprisingly straightforward once you understand the technology. We are going to look at why this is such a tricky problem and then walk through exactly how the right machine solves it with precision and speed.

Why Is Counting Mixed Candies So Difficult?

You've tried filling by weight, but your piece counts are still all over the place. This inconsistency is frustrating and costly. Understanding the root cause is the first step to fixing it.

Counting mixed candies is hard because individual pieces don't have the same weight. A bag that weighs 100 grams might have 48 pieces one time and 52 the next. Sticking and clumping also create major errors for standard equipment.

Let’s dive deeper into the core challenges with mixed chocolate candy (like the assortment in the image: Dark Cocoa, White Berry, Sea Salt Caramel, Peanut Butter, Mint Crunch). On the surface, “fill by weight” sounds easy. But in real production, weight-based filling breaks down fast when customers expect a stable piece count.

Here’s a table that shows how tiny weight differences impact a 400-gram bag:

| Candy Type | Average Weight | Pieces in a 400g Bag |

|---|---|---|

| Dark Cocoa | 10g | 8 pieces |

| White Berry | 9g | 8 pieces |

| Sea Salt Caramel | 11g | 8 pieces |

| Peanut Butter | 12g | 6 pieces |

| Mint Crunch | 8g | 11 pieces |

Another major issue is clumping, especially with sticky gummies. Volumetric fillers or simple weighers can't tell the difference between one piece and three pieces stuck together. This leads to huge inaccuracies and unhappy customers.

How Does a Modern Weigher Count Pieces Accurately?

You know the problem. Now you need a reliable solution that doesn't slow down production. Investing in the wrong "counting" machine can be a costly mistake.

A modern multihead weigher with a counting function uses a sample average piece weight to program its logic. The machine's computer then rapidly calculates hopper combinations to hit the target piece count, using weight as a reference for accuracy and speed.

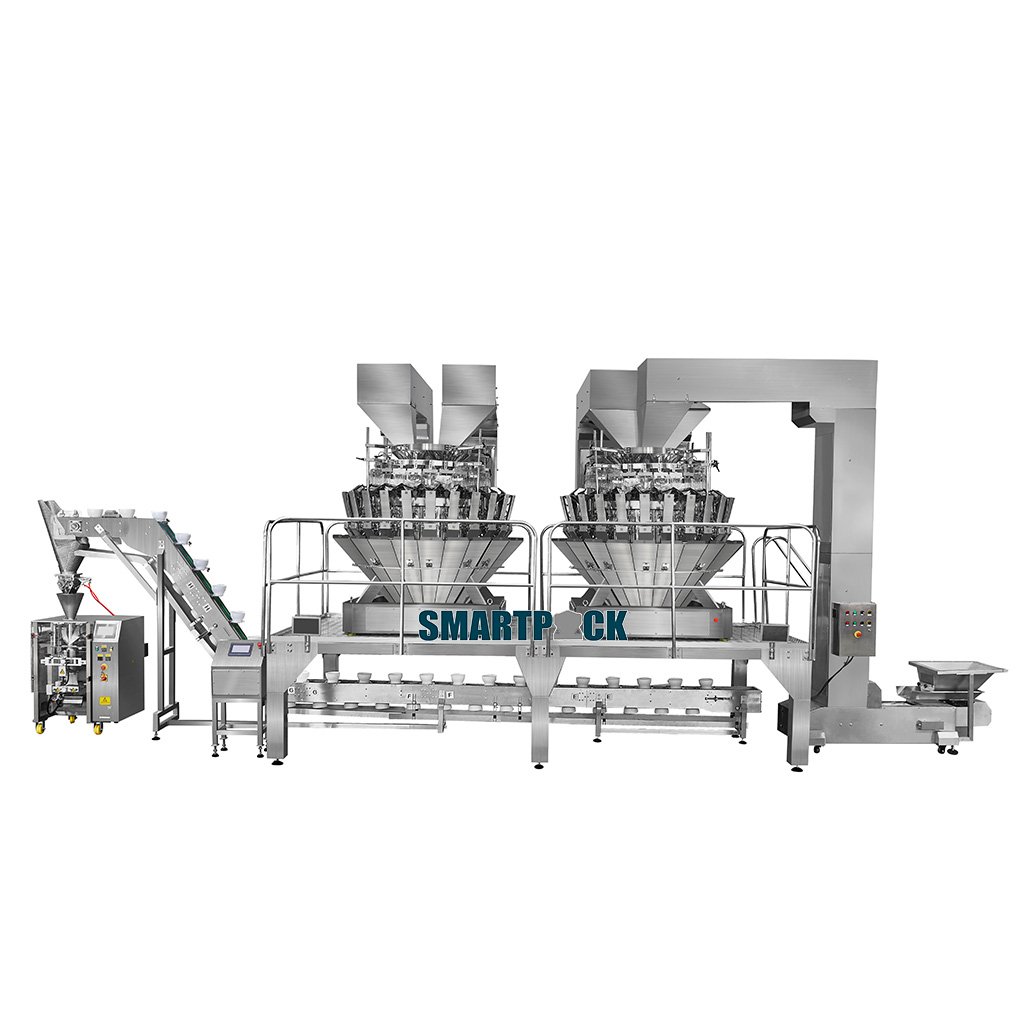

This is where advanced technology completely changes the game. At Smartpack, this is the exact problem we designed our multihead weighers to solve. It’s not magic; it’s a smart combination of mechanics and software. We moved beyond simple weighing to create a system that thinks in terms of pieces. The process is both fast and incredibly accurate, making it perfect for high-speed candy packaging lines. I’ve seen it firsthand transform a line that was struggling with giveaway rates of over 10% into one that hits the target count on more than 99% of its bags.

The technology works in a few simple steps:

- Calibration: First, the operator programs the machine with the average weight of a single piece of candy. This is easy to do by weighing a small sample.

- Combination Calculation: The candy is fed into the 10 to 32 individual weigh hoppers at the top of the machine. The weigher's processor then instantly calculates thousands of possible combinations of these hoppers to find the one that adds up to the target piece count. For a target of 50 pieces, it might combine hoppers containing 5, 8, 11, 7, 9, and 10 pieces.

- Smartpack's Logic (Weight + Count): This is our key advantage. Our system doesn't just count. It uses the weight data as a check. It knows that 50 pieces should weigh approximately 105 grams. This allows it to reject any combination that has a suspicious weight, which could be caused by clumps or misshapen pieces, ensuring the highest accuracy.

This combination of speed and intelligent cross-checking delivers consistent piece counts bag after bag, without slowing down your production.

What Is the Best Machine for Packing Counted Candy?

You have the perfect counting solution, but how do you get the candy into the bag? The wrong packaging machine can create bottlenecks. We'll show you the ideal setup.

The best machine setup is a Smartpack multihead weigher with piece counting, integrated directly with a Vertical Form Fill Seal (VFFS) machine or a rotary premade pouch packer. This creates a seamless, automated line for perfect bags.

As I mentioned in one of our successful case studies, solving the counting problem is only half the battle. You need a complete, integrated system to turn that accurately counted product into a finished, sealed bag ready for shipping. At Smartpack, we don't just sell you a weigher; we provide the entire solution. Our multihead weighers with piece counting are designed to work perfectly with our packaging machines. This creates a single, streamlined system that runs smoothly and efficiently. We've helped many candy manufacturers achieve this, moving them from messy, manual processes to fully automated lines.

Here are the two top choices for a complete line solution:

1. The Multihead Weigher + VFFS Line

This is the workhorse for high-volume candy production. The VFFS machine forms bags from a roll of film, our multihead weigher drops the precisely counted candy mix into the bag, and the machine seals it. It’s fast, efficient, and can produce a variety of bag styles like pillow bags and gusseted bags.

| Feature | Benefit |

|---|---|

| High Speed | Produces up to 40 bags per minute, depending on the product. |

| Cost-Effective | Using film from a roll is cheaper than buying premade pouches. |

| Flexible | Can easily switch between different bag sizes and styles. |

2. The Multihead Weigher + Rotary Pouch Packer Line

For brands that want a more premium look, this is the perfect solution. This line uses premade stand-up pouches. The rotary machine picks up a pouch, opens it, signals the weigher to drop the counted candy, and then seals it. It’s ideal for grabbing customer attention on the shelf.

This integrated approach ensures there are no communication errors between the weigher and the bagger, leading to less downtime and higher overall efficiency for your entire operation.

Conclusion

To solve inconsistent counts in mixed candy bags, use a Smartpack multihead weigher with piece counting. Combine it with a VFFS or pouch packer for a complete, accurate, and automated solution.