Struggling with slow, manual thermoforming machine feeding? This bottleneck limits your output and increases labor costs. We have a solution to automate and accelerate your entire process.

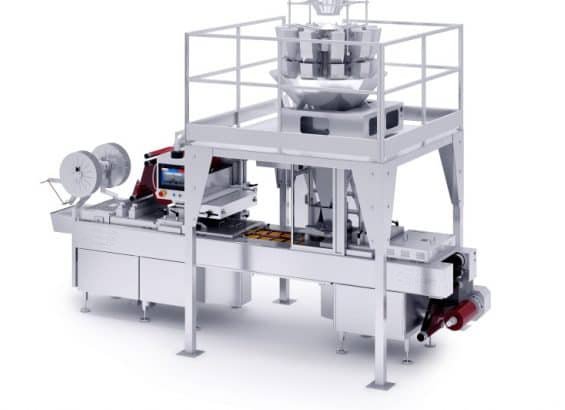

The most effective way to boost production is by integrating a multihead weigher1 with your thermoforming packing machine2. This automates the weighing and filling process, eliminating manual labor bottlenecks and significantly increasing throughput, speed, and accuracy on your production line.

Manually placing products into your thermoforming machine is a common practice. It seems simple enough when you're starting out. But as your orders grow, you quickly realize that your team can't keep up. The machine is waiting for product, an expensive piece of equipment sitting idle. You start wondering if there's a better way to feed it, a way to unlock its true potential. There is, and it involves a technology that many thermoforming machine users and even some manufacturers might not be aware of. Let's explore how you can transform your production line from a manual crawl to an automated sprint.

How can a multihead weigher automate your thermoforming line?

Are manual errors and inconsistent weights hurting your thermoforming line's efficiency? Automating this step seems complex, but it is simpler than you think and delivers immediate gains.

A multihead weigher1 automates your line by precisely weighing the product and then depositing it directly into the formed trays. A special filling device synchronizes the weigher's drops with the thermoformer's cycle, ensuring a seamless, high-speed operation3 without manual intervention.

Automating your thermoforming line with a multihead weigher transforms your workflow from a series of disjointed manual steps into a single, continuous, and efficient process. This integration closes the gap between weighing and packaging, which is where most bottlenecks occur. We have seen this transformation many times with our clients.

The Automated Workflow Explained

The process is designed for maximum efficiency. First, your product is elevated to the top of the multihead weigher1. The weigher's advanced software then calculates the perfect combination of weigh buckets to achieve your exact target weight. Finally, the product is released through our custom-designed filling device4, which directs the precise portions into multiple trays at once. This entire action is timed perfectly with your thermoforming machine's cycle, so there is no wasted time or motion. The result is a smooth, fast, and reliable packaging process.

| Feature | Manual Feeding | Multihead Weigher Automation |

|---|---|---|

| Speed | Limited by operator dexterity | Matches thermoformer's max speed |

| Accuracy | Inconsistent, high giveaway | High precision, minimal giveaway |

| Labor | Requires multiple operators | Requires minimal supervision |

| Hygiene | Increased product handling | Reduced contact, improved sanitation |

| Uptime | Prone to stops and starts | Continuous, consistent operation |

What makes the Smart Weigh solution unique for this process?

Finding an automation solution that fits your specific thermoformer can be a challenge. Standard equipment does not always work, leaving you with a mismatched and inefficient system.

Our solution is unique because we design a special filling device5 that perfectly integrates our multihead weigher with your thermoformer. It allows for simultaneous filling of 2 or 4 trays per cycle, a capability that very few suppliers worldwide can offer.

Many companies can sell you a weigher, but very few can provide a truly integrated solution for thermoforming lines6. The reason is that standard funnels or chutes simply do not work. They cannot deposit product accurately into multiple trays at high speed. This is where our expertise makes a significant difference.

Our Custom-Engineered Filling Device

We developed a specialized filling device to solve this exact problem. This is not an off-the-shelf part; it is an engineered component designed specifically to bridge the a multihead weigher1 and a thermoforming machine. This device can be configured to fill two, four, or even more trays with each cycle of the weigher. It ensures that every portion of product lands cleanly in the center of the tray, every single time, without spilling.

Why This Matters for Your Production

This custom integration is what unlocks the full potential of your thermoforming machine. It allows the weigher to keep pace with even the fastest thermoformers, ensuring your line is always running at its peak capacity. We are one of the only suppliers in China, and indeed globally, with the experience and capability to provide this complete, proven solution. We do not just sell machines; we analyze your entire process to deliver a system that works seamlessly from day one.

A Proven Process for Seamless Integration

Many of our clients use top-tier thermoforming machines from brands like ULMA and MULTIVAC. For them, the process is incredibly simple. They provide us with the machine and tray drawings, along with their factory's height and available area. With this information, we design a complete, integrated system including conveyors, the multihead weigher, and the custom multiple filling device. Most importantly, we handle the critical task of signal integration. We ensure our new equipment and their existing machinery communicate flawlessly, creating a seamless, unified production line.

How do you choose the right multihead weigher1 for your thermoformer?

Are you afraid of investing in a weigher that cannot keep up with your thermoformer or handle your product? Choosing the wrong model can be a very costly mistake.

Choosing the right weigher involves matching its specifications to your needs. We analyze your thermoformer's speed, your product's characteristics, and your required accuracy to recommend the perfect multihead weigher model for optimal performance.

Selecting the correct multihead weigher is not just about buying the fastest or largest model. It is a technical decision that requires a careful analysis of your specific application. A mismatch between the weigher and your line will lead to frustration and lost production. That is why we work closely with our clients to specify the perfect machine.

Key Factors for Selecting a Weigher

We consider several critical factors to ensure you get the right solution. The weigher's speed must be fast enough to complete a full weighing and depositing cycle before the thermoformer moves to the next set of trays. The characteristics of your product, whether it is sticky like marinated meat, fragile like salad, or frozen, will determine the design of the weigher's buckets and vibration profiles7. Finally, your accuracy requirements8 are crucial for minimizing product giveaway9 and maximizing profitability. We consider all these variables to propose a weigher that is a perfect match.

| Factor | Consideration | Why It's Important |

|---|---|---|

| Speed | Must match or exceed thermoformer's packs-per-minute rate. | A slow weigher creates a new bottleneck, defeating the purpose of automation. |

| Product Type | Is the product fragile, sticky, frozen, or dusty? | The weigher's design must prevent product damage or sticking for accurate weights. |

| Accuracy | Required weight tolerance (e.g., +/- 1.5g). | High accuracy reduces product giveaway, directly impacting your bottom line. |

| Tray Layout | How many trays across? What is the distance between them? | The filling device must be custom-designed to deposit product perfectly into each tray. |

Conclusion

By integrating a custom-fitted multihead weigher, you can fully automate your thermoforming line. This boosts speed and improves accuracy, moving your production far beyond its previous manual limits.

Understanding multihead weighers can help you optimize your production line and reduce manual labor. ↩

Explore the advantages of thermoforming packing machines to enhance your packaging efficiency. ↩

Discover technologies that can enhance the speed and efficiency of your manufacturing processes. ↩

Find out how custom filling devices can optimize your production line for better results. ↩

Learn how specialized devices can significantly boost your production efficiency. ↩

Explore integrated solutions that can enhance the performance of your thermoforming operations. ↩

Learn how vibration profiles can impact the accuracy and efficiency of your weighing systems. ↩

Explore the importance of accuracy in weighing systems to minimize product giveaway. ↩

Minimizing product giveaway is crucial for improving profitability in manufacturing. ↩