In the competitive nuts industry, efficient and reliable packaging solutions are critical for maintaining product quality, reducing operational costs, and meeting increasing consumer demands. This is especially important for products like nuts, dried fruit, and other snack foods. This case study explores how our client, a leading nuts producer, leveraged SmartPack’s nuts packing machine to overcome common industry challenges, enhance production efficiency, and improve product quality.

Case Study: Automatic Nuts Pouch Packaging Machine Line

The Problems are Facing:

Our client was struggling with inefficient packaging processes that led to inconsistent product quality, high material waste, and increased operational costs. Their existing manual packaging methods were unable to keep up with growing demand, resulting in delays and customer dissatisfaction.

After using Smartpack nuts packing machine:

- Increased Efficiency: Packaging speed increased by 40%, allowing our client to meet customer demands without delays and receive more orders.

- Faster Filling Process: The latest automation technologies and customizable options enabled a faster filling process, enhancing productivity in snack packaging operations.

- Reduced Waste: Material waste was reduced by 20%, resulting in significant cost savings.

- Improved Product Quality: Consistent, airtight sealing preserved product freshness and reduced customer complaints.

- Reliability and Support: The machine’s quick changeovers and seamless integration help to reduce downtime by ensuring smooth and continuous operation.

The Implementation:

- Machine Installation: The nuts packing machine was seamlessly integrated into client’s existing production line.

- Customization: The machine was configured to handle various pouch sizes and materials specific to NutriSnack Foods’ product range.

- Training: Staff received comprehensive training to ensure efficient operation and maintenance of the machine.

The Solution: SmartPack’s Nut Packaging Machine

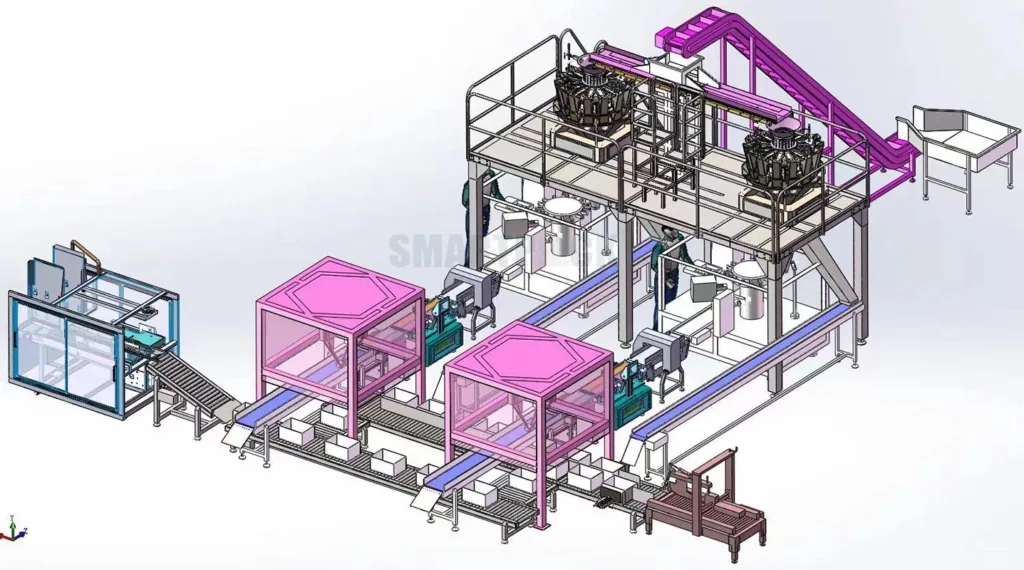

Overview of the Machine

- Infeed conveyor

- Multihead weighers

- Support platform

- Rotary pouch packing machines

- Metal detector and checkweigher

- Case erector

- Parallel Robot (box packing)

- Case sealer

SmartPack’s nuts packing machine is designed specifically to address the unique challenges of nuts packaging. It features:

- Fully automatic process from feeding, weighing, filling, packing, sealing to cartoning.

- High-Speed Operations: Capable of achieving speeds of up to 45 packs per minute with zipper pouches.

- Advanced Weighing System: Multihead weigher ensures precise portion control, reducing waste.

- Customizable Pouch Options: Accommodates various pouch sizes and materials to meet branding and packaging requirements.

- Auto Cartoning method: instead of manual effort, a robot picks and places finished pouches into cartons; it is equipped with a case unpacker and a case sealer for a fully automated process.

Why Choose SmartPack’s Nuts Packing Machine?

Customization and Flexibility:

Whether you’re packaging almonds, cashews, or mixed nuts, SmartPack’s machine can be tailored to meet your specific needs, offering flexibility in pouch size, shape, and material. It is designed to handle various nut products efficiently, and the quick changeover feature ensures high operational speeds, allowing for faster transitions between different packaging formats.

Reliability and Support:

With local machine installation and training service, 24/7 customer support and a reputation for reliability, SmartPack ensures that your production line runs smoothly, minimizing downtime and maximizing productivity.

Proven Results:

SmartPack’s nuts pouch packing machine delivers tangible results, from increased efficiency to improved product quality.

Conclusion and Call to Action

Investing in SmartPack’s nuts packing machine is a strategic decision for enhancing the packaging system and snack packaging efficiency, reducing waste, and improving product quality. If you’re ready to optimize your packaging process and meet the demands of a growing market, contact SmartPack today for a consultation and see how our solutions can benefit your business.