Have you ever grabbed a bag of chips or a handful of candy and wondered how it all ends up so perfectly packed? The answer lies in snack packing machines—the behind-the-scenes stars of the snack food world! These machines take loose snacks like popcorn, nuts, or pretzels and transform them into neatly sealed packages ready for your enjoyment. If you’re new to this topic or dreaming of launching your own snack business, this guide is your one-stop introduction. We’ll break it all down in a simple, friendly way—covering what these machines are, how they work, the different types available, their benefits, and how to pick the perfect one. Ready to explore? Let’s get started!

What Are Snack Packing Machines and Why Should You Care?

The Basics: What They Are

Snack packing machines are automated systems designed to package snack foods into bags, pouches, jars, or other containers. They handle everything from measuring the right amount of snacks to filling and sealing the package—all without breaking a sweat! Think of them as tireless robots that streamline the process, ensuring your favorite treats are ready to hit the shelves in no time.

Why They Matter in Today’s World

Snacks are a massive industry. Experts predict the global snack food market will soar to $658.49 billion by 2032, driven by our love for quick, tasty bites. Snack packing machines are the backbone of this growth, helping companies meet skyrocketing demand. They pack snacks faster than human hands ever could, maintain consistent quality, and keep products fresh and safe. For businesses, they’re a lifesaver—cutting costs and boosting efficiency. For you as a consumer, they ensure every bag of chips or jar of nuts is just right.

Why This Matters to You

Whether you’re a snack enthusiast curious about the process or an entrepreneur eyeing a new venture, understanding snack packing machines opens up a world of possibilities. Stick with us as we unpack (pun intended!) everything you need to know!

How Do Snack Packing Machines Work? A Simple Breakdown

The Step-by-Step Process

Snack packing machines might sound high-tech, but their process is surprisingly straightforward. Here’s how they turn a pile of snacks into a sealed package:

- Feeding the Snacks: It all starts with a big container called a hopper, where snacks are loaded. Alternatively, a conveyor belt—a sort of snack highway—brings them in.

- Measuring the Amount: The machine calculates the exact portion for each pack. For heavier snacks like nuts, it uses weight; for lighter ones like popcorn, it might measure by volume.

- Filling the Package: The snacks are dropped into their new home—be it a bag, pouch, or jar.

- Sealing It Up: The package is closed tight, often with heat or pressure, to lock in freshness and keep out air or germs.

It’s like a tiny factory line, humming along to churn out pack after pack with precision and speed.

Key Components You’ll Find

To achieve their impressive functionality, snack packing machines rely on three critical components that work in harmony to deliver consistent, high-quality results. Let’s examine each one:

- Feeding Conveyor: This component serves as the initial entry point for the process. A precision-engineered conveyor belt efficiently transports snacks—such as nuts, chips, or popcorn—from a bulk supply into the machine, ensuring a steady and controlled flow to kickstart the packing operation.

- Weigher: At the heart of accuracy lies the weigher, an advanced measurement system designed to dispense the exact portion for each package. Utilizing sophisticated technology, it guarantees precise weights or volumes, eliminating inconsistencies and ensuring every pack meets stringent standards.

- Packing Machine: The cornerstone of the system, the packing machine handles the final stages with expertise. It receives the measured snacks, places them into designated containers—be it pouches, bags, or jars—and applies a secure seal, typically through thermal or mechanical means, to preserve freshness and product integrity.

Together, these components create a seamless workflow: snacks move smoothly along the feeding conveyor, are meticulously weighed, and are expertly packed and sealed—all within an optimized, automated sequence. This integration exemplifies the efficiency and reliability that define modern snack packing technology.

A Relatable Analogy

Think of a snack packing machine like a vending machine chef: it grabs the perfect portion, packs it neatly, and hands it over—except it’s making hundreds of “orders” per minute!

Types of Snack Packing Machines: Exploring Your Options

Not all snacks are the same, and neither are the machines that pack them. The right choice depends on your product and packaging goals. Let’s explore the main types, focusing on multihead weigher, vertical form fill seal machine, pouch packing machines and jar filling sealing machines, and spotlight the industry-favorite multihead weigher VFFS machine.

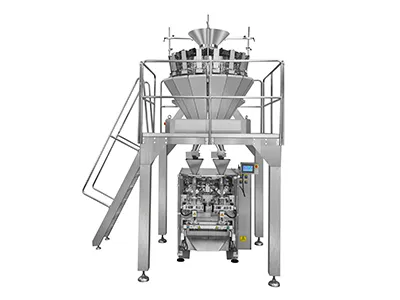

Multihead Weighers: The Precision Pros

If VFFS machines are the body of a snack packing line, multihead weighers are the brains. These advanced weighing systems ensure every pack gets the exact amount of product—down to the gram. Speed and accuracy are their superpowers, making them indispensable for snack manufacturers.

- How It Works: Snacks are fed into the top of the weigher, where they’re distributed into multiple small hoppers (typically 10 to 32, depending on the model). A computer calculates the best combination of hoppers to hit the target weight, then releases the portion into the packing machine below. It’s like a high-speed juggling act that never drops the ball.

- Key Features:

- Accuracy: Multihead weighers minimize overfills and underfills, ensuring consistent pack weights and happy customers.

- Speed: They keep up with fast-moving lines, weighing and dispensing in seconds.

- Flexibility: They can handle everything from delicate crackers to sticky candies or chunky trail mix.

- Why It’s Great for Snacks: For products sold by weight—like almonds or pretzels—multihead weighers guarantee precision. They also reduce product giveaway, saving you money in the long run.

Vertical Form Fill Seal (VFFS) Machines: The Snack Packing Powerhouse

A vertical form fill seal (VFFS) machine is a cornerstone of the snack packaging industry. It’s an automated system that transforms a flat roll of film into finished bags filled with your product—all in one seamless, vertical operation. Imagine it as a multitasking marvel that forms, fills, and seals bags with speed and precision.

- How It Works: The process starts with a roll of packaging film (usually plastic or a laminate). The VFFS machine pulls the film, wraps it around a forming tube to create a bag shape, seals the sides, fills it with snacks, and then seals and cuts the top and bottom. The result? A neatly packed bag ready for the shelf.

- Key Features:

- Speed: VFFS machines can churn out hundreds of bags per minute, making them perfect for high-volume production.

- Versatility: They handle various bag styles—like pillow bags, gusseted bags, or quad-seal bags—and can pack snacks of different shapes and sizes.

- Cost-Effectiveness: By forming bags from a roll of film, they reduce material waste and labor costs compared to using pre-made bags.

- Why It’s Great for Snacks: Whether you’re packing lightweight chips or heavier nuts, VFFS machines adapt to the job. Their ability to handle flexible packaging makes them a go-to for snack brands aiming for efficiency without sacrificing quality.

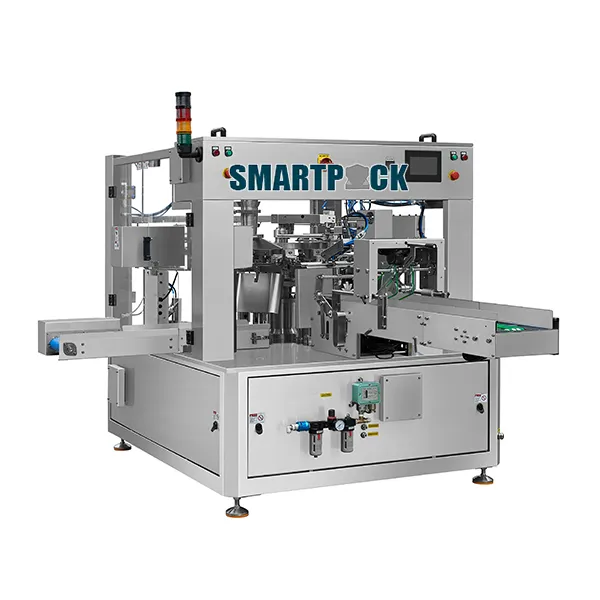

Pouch Packing Machines: Flexible and Versatile

Pouch packing machines are champs at handling lightweight, flexible packaging—perfect for snacks like chips, dried fruit, or granola.

- How They Work: These machines either use pre-made pouches or create them from a roll of film. They fill the pouch with snacks and seal it shut in one go.

- Why They’re Awesome: Pouches are lightweight, keep snacks crisp, and offer tons of room for eye-catching designs or resealable zippers.

- Best For: Crunchy snacks or anything needing a portable, user-friendly pack.

Jar Filling Sealing Machines: Sturdy and Secure

For snacks that need extra protection or a premium look, jar filling sealing machines step up.

- How They Work: Snacks are measured out, dropped into jars or cans, and sealed with lids—often using heat or pressure for an airtight finish.

- Why They’re Awesome: They shield snacks like nuts, candies, or popcorn from moisture and damage, plus they look great on a shelf.

- Best For: Durable packaging or high-end products that need to stand out.

Comparing Snack Packing Lines

Both VFFS machines and multihead weighers shine in different setups, depending on your packaging goals. Let’s compare three common lines that combine these technologies: the multihead weigher VFFS line, multihead weigher pouch packing machine line, and multihead weigher jar filling sealing line. Each has unique strengths tailored to specific snack packing needs.

Side-by-Side Comparison

Here’s a quick snapshot to see how these lines stack up:

| Packaging Line | Best For | Speed | Packaging Type | Strength | Weakness |

|---|---|---|---|---|---|

| Multihead Weigher VFFS Line | High-volume bagged snacks | Very High | Flexible bags | Speed and affordability | Limited to bags |

| Multihead Weigher Pouch Packing Line | Premium or specialty snacks | Moderate | Pre-made pouches | Customizable, eye-catching design | Slower, higher pouch cost |

| Multihead Weigher Jar Filling Line | Protective or premium packaging | Low to Moderate | Rigid jars/cans | Durability and shelf appeal | Higher cost, slower production |

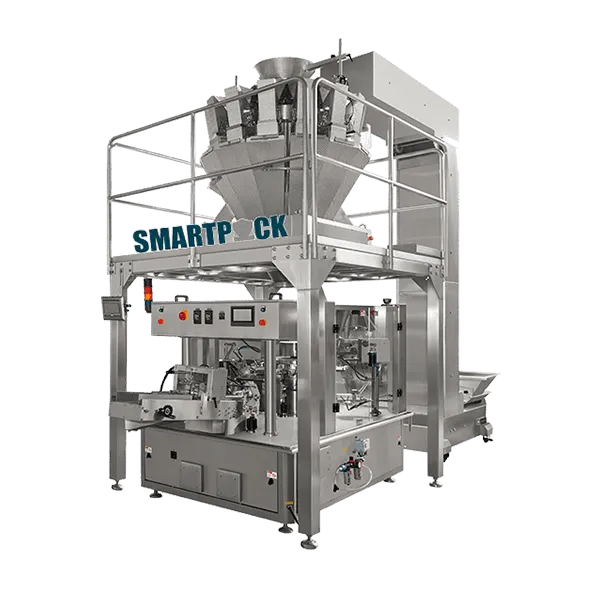

1. Multihead Weigher VFFS Line

This setup pairs a multihead weigher with a VFFS machine for a fast, efficient bagging process.

- What It Does: The multihead weigher measures out precise portions, and the VFFS machine forms bags from a film roll, fills them, and seals them shut—all in one continuous flow.

- Best For: High-volume snacks like chips, popcorn, or granola that need quick, affordable packaging.

- Advantages:

- High Speed: Capable of producing hundreds of bags per minute, it’s a champion of mass production.

- Cost-Effective: Using film rolls instead of pre-made bags keeps material costs low.

- Streamlined: Combines forming, filling, and sealing into one machine, reducing labor needs.

- Drawbacks: Limited to flexible bags, so it’s not ideal for rigid containers like jars.

2. Multihead Weigher Pouch Packing Machine Line

This line uses pre-made pouches instead of forming bags on the fly, offering a different approach to snack packing.

- What It Does: The multihead weigher portions the snacks, and the pouch packing machine fills and seals pre-made pouches—like stand-up pouches or resealable bags.

- Best For: Premium or specialty snacks, such as gourmet trail mix or dried fruits, where packaging design matters.

- Advantages:

- Design Flexibility: Pre-made pouches can feature unique shapes, zippers, or bold branding.

- Premium Appeal: Stand-up pouches often look more upscale on the shelf.

- Adaptability: Works with various pouch sizes and styles without changing film rolls.

- Drawbacks: Slower than VFFS lines and may require more manual setup for pouch loading, increasing operational costs slightly.

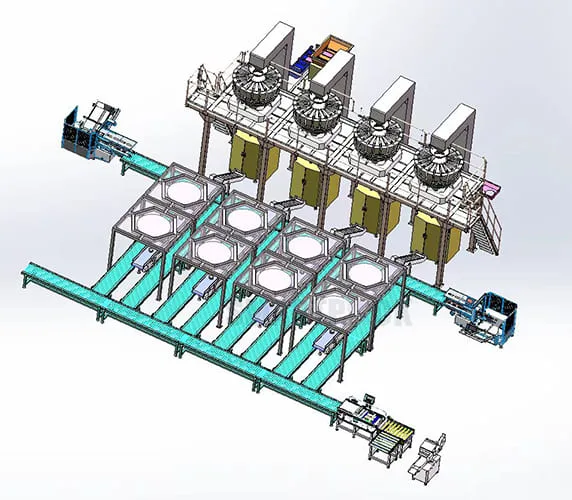

3. Multihead Weigher Jar Filling Sealing Line

For snacks that need sturdier packaging, this line swaps bags for rigid containers.

- What It Does: The multihead weigher ensures accurate portions, and the jar filling sealing machine fills and seals jars, cans, or other rigid containers.

- Best For: Snacks like nuts, candies, or premium popcorn that benefit from protection or a high-end look.

- Advantages:

- Durability: Jars protect fragile or perishable snacks from crushing and air exposure.

- Shelf Presence: Rigid containers stand out and convey quality, appealing to upscale markets.

- Longevity: Airtight seals extend shelf life, ideal for snacks sold in bulk.

- Drawbacks: Slower and more expensive than bag-based lines due to the cost of jars and additional handling steps.

The Industry Star: Multihead Weigher VFFS Machine

The multihead weigher Vertical Form Fill Seal (VFFS) machine is the rockstar of snack packing—and for good reason:

- Precision Power: Its multihead weigher uses multiple scales to measure snacks accurately, ensuring every pack is spot-on.

- Speed and Efficiency: It forms bags from a film roll, fills them, and seals them in one continuous motion—fast and seamless.

- Versatility: From chips to candies to pretzels, it handles almost any snack with ease.

This combo of accuracy, speed, and adaptability makes the multihead weigher VFFS the go-to choice for snack businesses worldwide.

Smartpack’s Tailored Solutions

Looking for a machine that matches your production needs? Smartpack has you covered with options for every speed:

- 60 packs per minute: Ideal for small startups or niche brands testing the waters.

- 80-120 packs per minute: Perfect for growing businesses scaling up their output.

- 300-600 packs per minute: High-speed solutions for large-scale producers pumping out thousands of packs hourly.

For those pushing the limits, Smartpack offers auto cartoning machines (to box up packs) and palletizing machines (to stack them for shipping). These extras turn your packing line into a fully automated powerhouse—efficiency at its finest!

The Benefits of Snack Packing Machines: Why They’re Worth It

Why invest in a snack packing machine? The perks are hard to ignore. Here’s what they bring to the table:

Lightning-Fast Production

These machines are speed demons! While a person might pack a few dozen bags an hour, a machine can crank out hundreds—or even thousands—in the same time. That’s a game-changer for keeping up with snack-crazy customers.

Cost Savings Over Time

Yes, the upfront cost can sting, but the long-term payoff is huge. Machines reduce labor needs—fewer hands on deck mean lower payroll. Plus, their precision cuts waste; no more overfilled bags eating into your profits. It’s an investment that keeps on giving.

Consistent Quality Every Time

Ever notice how every bag of your favorite snack looks identical? That’s the machine’s magic. They deliver uniform weight, size, and sealing, making your product look professional and keeping customers coming back for more.

Safety and Freshness Guaranteed

Machines minimize human contact, reducing the risk of contamination—a big win for food safety. Their tight seals block out air, moisture, and germs, ensuring snacks stay fresh longer. That’s not just good for you; it’s a must for meeting strict health regulations.

Bonus: Scalability

Start small with a basic machine, then upgrade as your business grows. They’re flexible enough to grow with you, making them a smart choice for any stage of your snack journey.

How to Choose the Right Snack Packing Machine: Tips for Newbies

Ready to pick a machine? Here’s a beginner’s checklist to find the perfect fit:

Step 1: Understand Your Snack

What are you packing? Crunchy chips need different handling than sticky gummies or fine powders like seasoning. Ask yourself:

- What’s my snack type?

- Do I want pouches, jars, or something else?

- How many packs do I need daily?

Your answers will steer you toward the right machine.

Step 2: Set Your Budget

Machines range from budget-friendly models (a few thousand dollars) to heavy-duty systems (hundreds of thousands). Start with what you can afford, but don’t skip hidden costs like maintenance, repairs, or electricity. A little planning goes a long way!

Step 3: Check Your Space

Measure your workspace before you buy. Some machines are compact, while others need room to spread out. Pick one that fits without turning your setup into a Tetris game.

Step 4: Lean on Supplier Support

Choose a supplier who’s more than just a seller. Look for:

- Setup help or installation services.

- Training for you or your team.

- A trial period or demo to test the machine.

Good support can make or break your experience, especially if you’re new to this.

Step 5: Think Long-Term

Will this machine grow with you? Consider future needs—like higher speeds or different packaging types—so you’re not out shopping again too soon.

Your Snack Packing Adventure Begins!

Quick Recap

Snack packing machines are your ticket to fast, efficient, and high-quality packaging. From pouch packing machines for chips to jar fillers for nuts—and the ever-popular multihead weigher VFFS—they offer speed, savings, and safety. Smartpack’s range, from 60 to 600 packs per minute, ensures there’s a solution for every business size.

Take the Next Step

Curious to learn more? Browse supplier sites, watch machine demos online, or reach out to experts for advice. The snack packing world is buzzing with opportunity—why not jump in?

Let’s Chat!

Got questions or ideas to share? Drop them in the comments—we’d love to connect and help you kickstart your snack packing journey!