A linear weigher is a type of weighing machine that’s all about accuracy and consistency. The machine, is a standalone system, with its keen sense of weight, decides exactly when it’s hit the target weight. Smartpack’s linear weighing machine is made of good grade stainless steel 304, the weigh hoppers connect load cell for great accuracy.

What are the components that make linear weighing machine up?

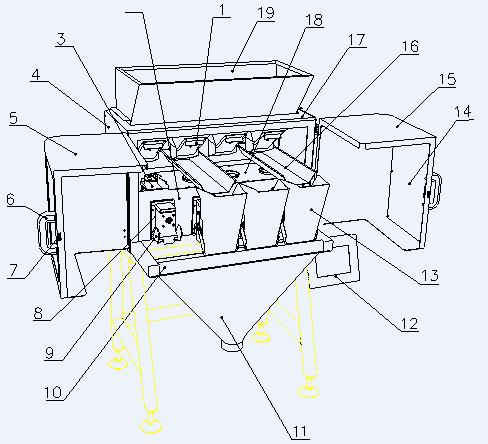

| No. | Description | No. | Description |

| 1 | Upper insert BD | 11 | Dump chute |

| 2 | Machine frame | 12 | Touch screen |

| 3 | Vibrator | 13 | Weigh hopper |

| 4 | Seal board | 14 | Transparent BD |

| 5 | Left door | 15 | Right door |

| 6 | Handler | 16 | Vibrator pan |

| 7 | Magnet | 17 | Machine stand 1 |

| 8 | Actuator | 18 | Upper cover |

| 9 | Weigh hopper support | 19 | Upper funnel |

| 10 | Machine stand 2 |

What Common Applications and Industries Using Linear Weighers?

Linear weighers are versatile and find applications in a wide range of industries. Some of the most common include:

- Food Industry: From snacks, grains, to frozen foods, pet food or even granular powders. linear weighers handle various free flowing dry products, ensuring precise portion control.

- Pharmaceuticals: Accuracy is crucial in pharmaceuticals, and linear weighers provide the precision needed for packaging pills, capsules, and powders.

- Agriculture: Seeds, feed, and fertilizers are commonly weighed and packaged using linear weighers.

- Chemicals: Whether it’s powders or granules, linear weighers can handle various chemical products with ease.

How many types of linear weigher?

There are a few different types of linear weighers available, weighing range from those designed for objects up to 50kgs in weight, but here we only discuss the linear weigher for small weight 100-10kg. Smartpack manufactures mainly 3 types linear weigher: vibrating linear weighers, screw linear weighers and belt linear weighers.

Vibrating linear weighers are the most common type linear weigher. It uses a vibrating pan which evenly distributes the product into the weighing hoppers. The vibration helps to ensure that each object is accurate weighing. This type of linear weighers can weigh granular products such as rice, beans, seeds, sugar and even some spices including coffee powder, washing powder and etc.

Screw linear weighers utilize an auger screw to move the product to weigh hopper. This type of weigher is ideal for sticky food such as meat.

Finally, belt linear weighers are the customized one. The belt moves the product across the weighing hopper in an efficient manner.

How does linear weigher work?

The feeding pans deliver the products to hoppers, then hoppers which connect with load cell measure the weight of the item. When the actual weight reaches to the set weight, the feeding pan stop and hopper opens to fill products.

What are the benefits of using linear weighers?

Linear dosing machine offer a host of advantages compared with traditional digital scales and measuring cups. For one, one unit linear weigher could weigh many weight, just set it on touch screen, the weigher will weigh and reach the target weight. Second, linear weighing machines provide far more accurate precision than manual methods. Third, they can also be faster and more efficient than manual methods, allowing for quicker processing times. Finally, they are often more cost-effective in the long run, since they provide a consistent level of accuracy and reduce labor costs. The daily maintenance is also easy to clean, the weigh hoppers and feeding pan can be removed without any tools.

How many types of the linear weigher packaging machines system?

- Vertical packing machine with linear weigher

- Doypack packing machine with linear weigher

- Thermoforming packing machine with linear weigher

Where to buy linear weigher packaging machine?

Smartpack Machine is one of reliable linear weigher manufacturers from China, we are devoting in weighing packing machine for 10 years with professional R&D and sales team. We believe that we are not only your supplier but also your business parnter that help you business booming. Contact us to get linear weigher packaging machines quote now!

Conclusion and Future Trends in Linear Weighing Technology

As we look to the future, linear weighing technology continues to evolve. Advancements in AI and machine learning are set to make these machines even more efficient and intuitive.

In conclusion, linear weighers are an invaluable asset in modern production lines. Their precision, efficiency, and versatility make them indispensable in various industries. As technology advances, we can only expect these machines to become more integral to industrial processes.

Stay tuned for more innovations in linear weighing technology, and feel free to contact us for any inquiries or further information about our products and services!