If you are looking for an efficient and reliable way to pack mixtures of different items, then you should consider using a mixture packing machine. A mixture packing machine is a type of packaging equipment that is used to pack mixtures of different items. This type of machine is typically used in industrial and commercial applications, such as nuts packing, dry fruits packing, even frozen food packing and etc.

Mixture packing machines are designed to quickly and easily package a variety of items, regardless of their size or shape. In addition, a mixture packing machine can help improve your production efficiency and save you time and money in the long run.

How does a mixture packing machine work?

Genrally there are 2 types of mixture packing machine system, one is 1 unit mixture multihead weigher works with vertical form fill seal machine or rotary doypack machine; second is several units multi head scale integrated with vffs machines or pouch packing machine.

Let’s talk the solution which is 1 unit mixture weigher with packing machine firstly. This type mixture packing machine is used for nuts and dry fruits packing, the advantages are:

1. Save your workshop area

2. Higher speed performance

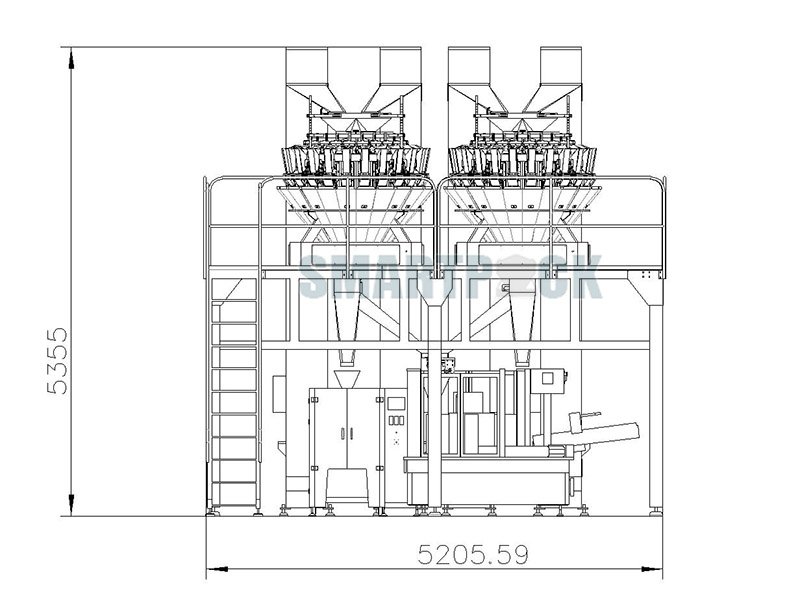

It consists of several units conveyor, 1 unit 24 head or 32 head multi head weigher, 1 unit packing machine, supporting platform, output conveyor, rotary table and etc.

Packing process overview:

Conveyors feed different products to the specific area of multihead weigher → multihead weigher auto weigh and fill → packing machine pack and seal the bags → finished bags output

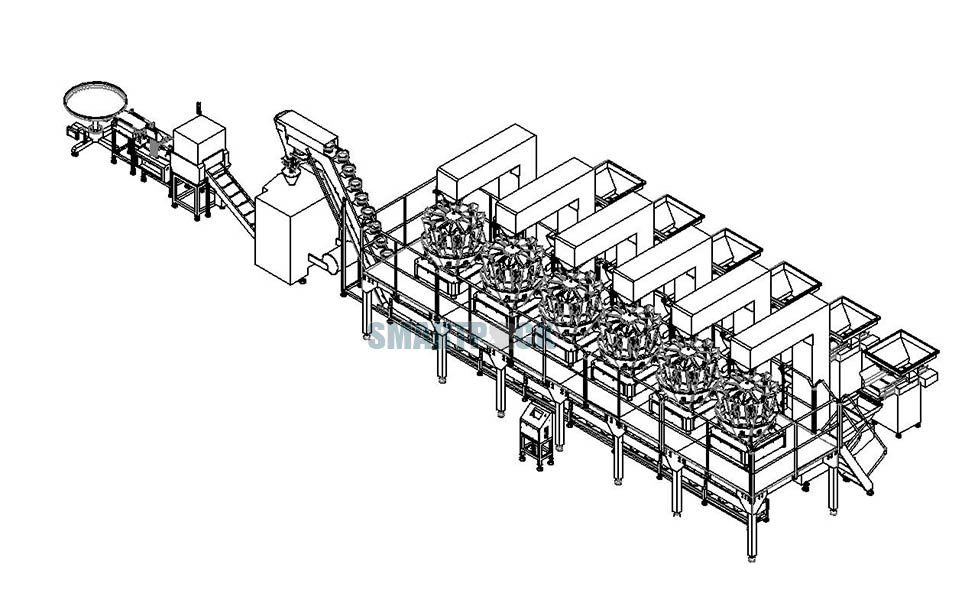

Then come to the second type of mixture solution, which we called double lift mixture packing system. It consists of several units multi head scale, product infeed conveyors, 1 unit packing machine, 1 unit bowls conveyor, support platform, output conveyor and etc.

This solution is recommended for more than 5 kinds of material mixture packing projects, the advantanges are:

1. Full automatic packing, save the labor cost and time

2. Higher speed and accuracy performance than labour work

Packing process overview:

Conveyors feed different products to multihead weigher → multihead weigher auto weigh and fill into bowl conveyor → bowl conveyor feed products to packing machine → packing machine pack and seal the bags → finished bags output

What are the benefits of using a mixture packing machine?

A mixture packing machine can help improve your production efficiency and offer a variety of benefits. First, by packaging a variety of items together, you can reduce the amount of time that is required to package each item individually. Second, a mixture packaging equipment can help you save money on material as the weigher accuracy is much higher. Finally, it can help improve your production speed by packaging items faster than you could if you were packaging them by hand. In addition, a mixture packing machine can help you save time and money in the long run by reducing the amount of labor that is required to package items individually.

How can you choose the right mixture packing machine for your business?

When choosing a mixture packing machine, you should consider the specific needs of your business. For example, you will need to determine the types of products that you will be packaging, the packaging materials that you will need, and the production speed that you require. In addition, you should consult with a knowledgeable packaging specialist to ensure that you choose a machine that is right for your business.

What are some of the common problems with mixture packing machines and how can you avoid them?

Common problems with mixture packing machines include jams, product damage, and excessive noise. To avoid these problems, you should regularly maintain your machine and follow the manufacturer’s instructions for use. In addition, you should consult with a machine specialist to ensure that you are using the right mixture packing machine for your business.

How to maintain a mixture packing machine for optimal performance?

To maintain your mixture packing machine for optimal performance, you should regularly clean, lubricate and check the machine. By the way, you should follow the manufacturer’s instructions for use and consult with a packaging specialist on a regular basis.

Regularly clean: clean your mixture packing machine on a regular basis to remove any dirt, dust, or debris that could build up and cause problems.

Regularly lubricate: You should lubricate your mixture packing machine on a regular basis to keep the moving parts working smoothly.

Regularly check: if the machine works long hours a day, you should check the machine parts which are easy to be weared and teared, such as sealing parts of packing machine, the pull belts of vffs machine and etc.